Unique ECL Technology

Electronically Controlled Load (ECL) and USP Minimum Weight Standard

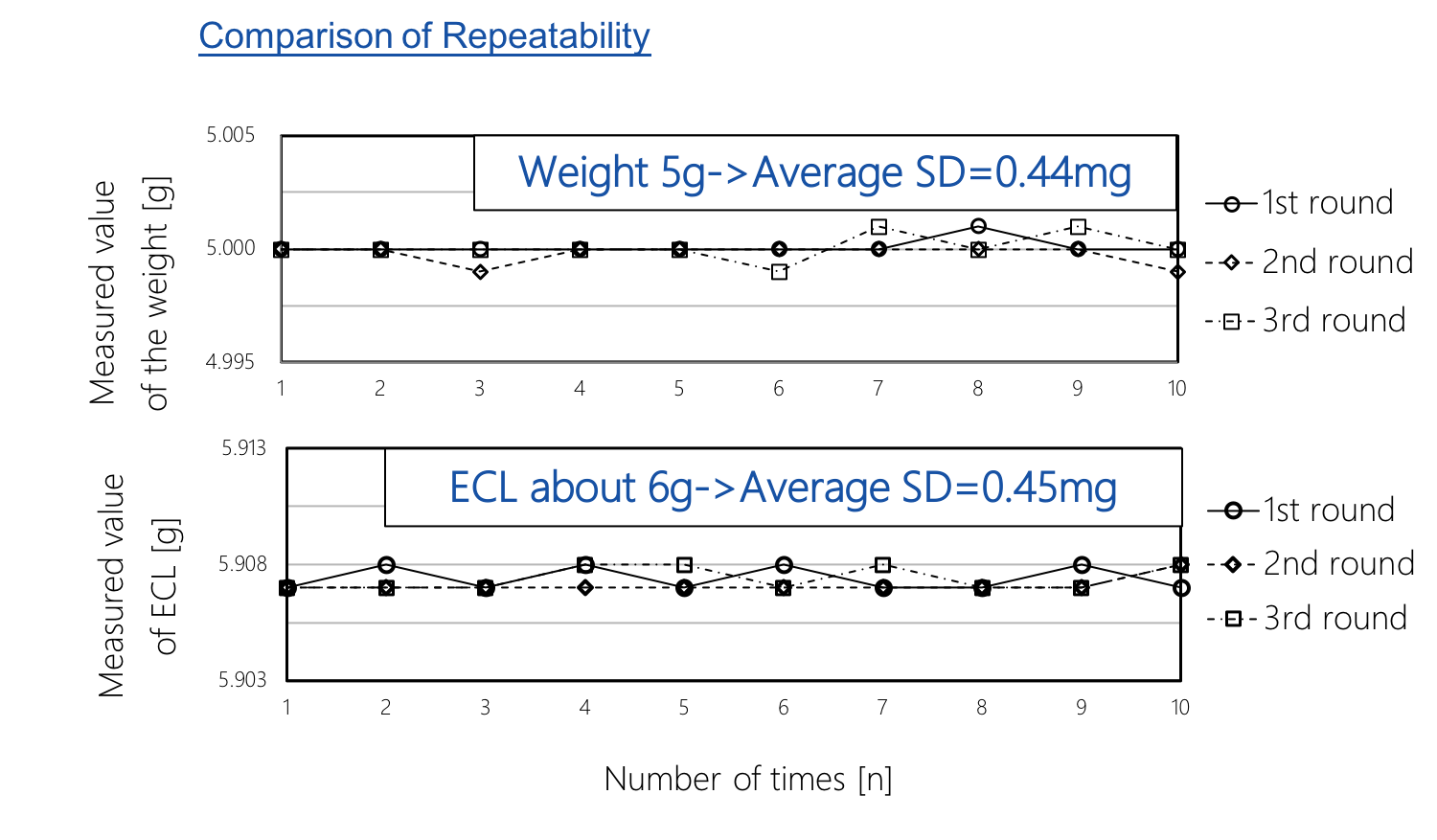

ECL is A&D’s unique technology (patent pending) of generating a minute load (0.3 to 3% of the balance capacity) by purposely altering the equilibrium state of the electromagnetic force restoration sensor. A balance with this technology, such as the Apollo GX-A/GF-A series, allows the user to test its repeatability performance without using an external weight by automatically calculating the standard deviation from 10 repeated measurements with the said artificially generated load. Further, based on the result of this repeatability test, the balance indicates the minimum weight in accordance with the United States Pharmacopeia (USP) standard. Currently, ECL can complete a repeatability test and minimum weight calculation in about a minute and a half.

While the principle of load sensing is exactly the same for ECL and an external weight, users may question the validity of the minimum weight produced by the former, as it is difficult to argue that ECL is the same as the “test weight” in the USP terms. They may also point to the fact that, with ECL, the influence of the operator's skill on repeatability isn’t taken into account.

ELECTRONICALLY CONTROLLED LOAD EXPLAINED

The difference between a repeatability test using ECL and using an external weight is like the difference between calibration using an internal (built-in) weight and using an external weight. In order to officially ensure and report accuracy, the balance needs to be calibrated using an external weight, because the correction can only be determined by an external weight. On the other hand, internal calibration is a simplified, informal method (the internal weight value can vary with time or during transportation, etc.). However, it is highly useful for daily accuracy management as it requires a much shorter time and absolutely no skill on the part of the operator.

Similarly, in order to strictly abide by the USP standard, A&D also advises that an external weight be used to test for repeatability and the minimum weight. Meanwhile, ECL provides a number of new and different benefits. Firstly, it is quick and easy, as with internal calibration. Secondly, users who do not know how to calculate the minimum weight can still determine the minimum amount of sample they need to weigh to be sure that their results are reliable. This should be good enough for those who are not required to document compliance with the USP standard, and much better than using the value provided as “typical” in manufacturers’ brochures, etc., because the minimum weight (repeatability) is greatly affected by environmental disturbances and therefore must be assessed where the balance is actually set up.

Thirdly, even when users ultimately have to obtain the minimum weight with an external weight, they can seek to make it as small as possible by finding the optimal installation settings by drawing on ECL in advance. Finally, ECL is extremely handy for daily performance management. For example, users may want to check repeatability three times a day (e.g. in the morning, afternoon and evening), which will be difficult if they are to use an external weight. Additionally, it is troublesome for many users to prepare, maintain and handle an appropriate test weight, which is often small (not more than 5% of the balance capacity).

IN CONCLUSION

A&D has long adhered to the policy of providing users with solutions that enable them to manage balance accuracy and performance easily by themselves while also trying to raise awareness that balance accuracy and performance are inseparable from environmental factors. This is why A&D developed such products as the AD-1687 weighing environment logger, the AD-1691 weighing environment analyzer, and various accessories to minimize the effects of external disturbances. ECL is one more of A&D’s efforts to pursue this policy.